BatteREuse #

Summary #

For the launch project as part of the GIX program, the GIX team partnered with UW-spinoff BattGenie to develop a use-case & market entry point for the nascent technology.

The GIX team developed a prototype Energy Storage System (ESS) and Battery Management System (BMS) for Lithium-ion batteries. It included a customer-facing dashboard that went through two rounds of usability testing.

This post is a rehash of our final report and final presentation. Feel free to explore those if you have more questions and for the references to all the data.

What is BattGenie?

BattGenie is a startup out of the University of Washington that has a more efficient way of charging Li-on batteries, allowing their life to be extended. They explain it on their own site better than I could, with graphics and everything. It’s worth checking out if you’re interested.

Problem Space #

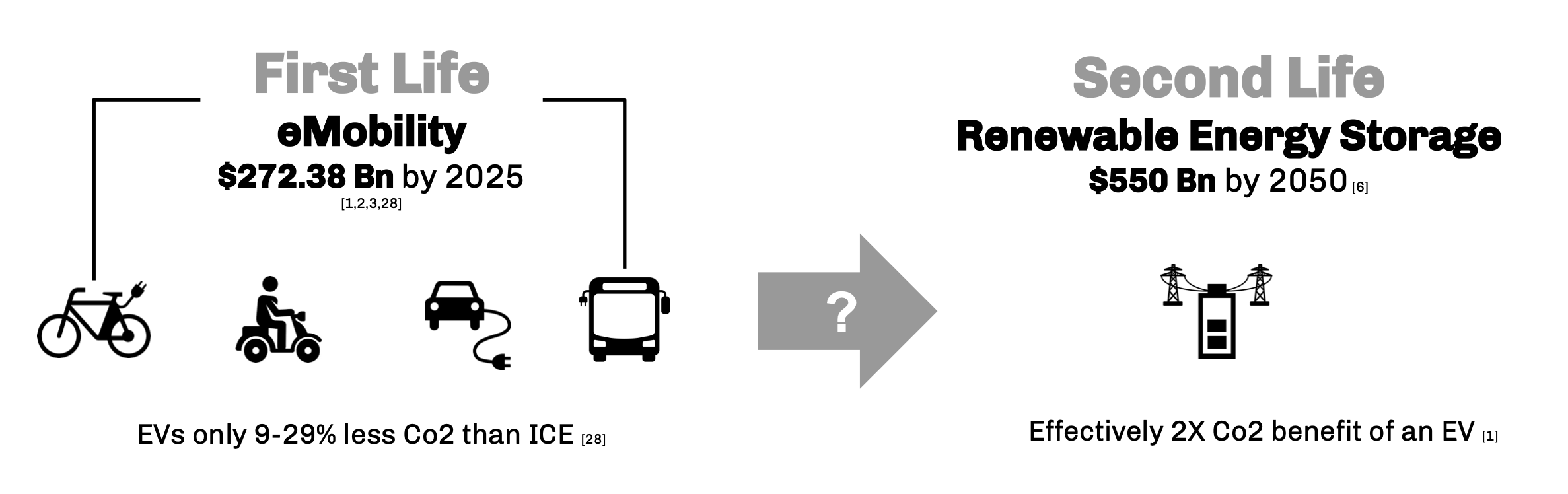

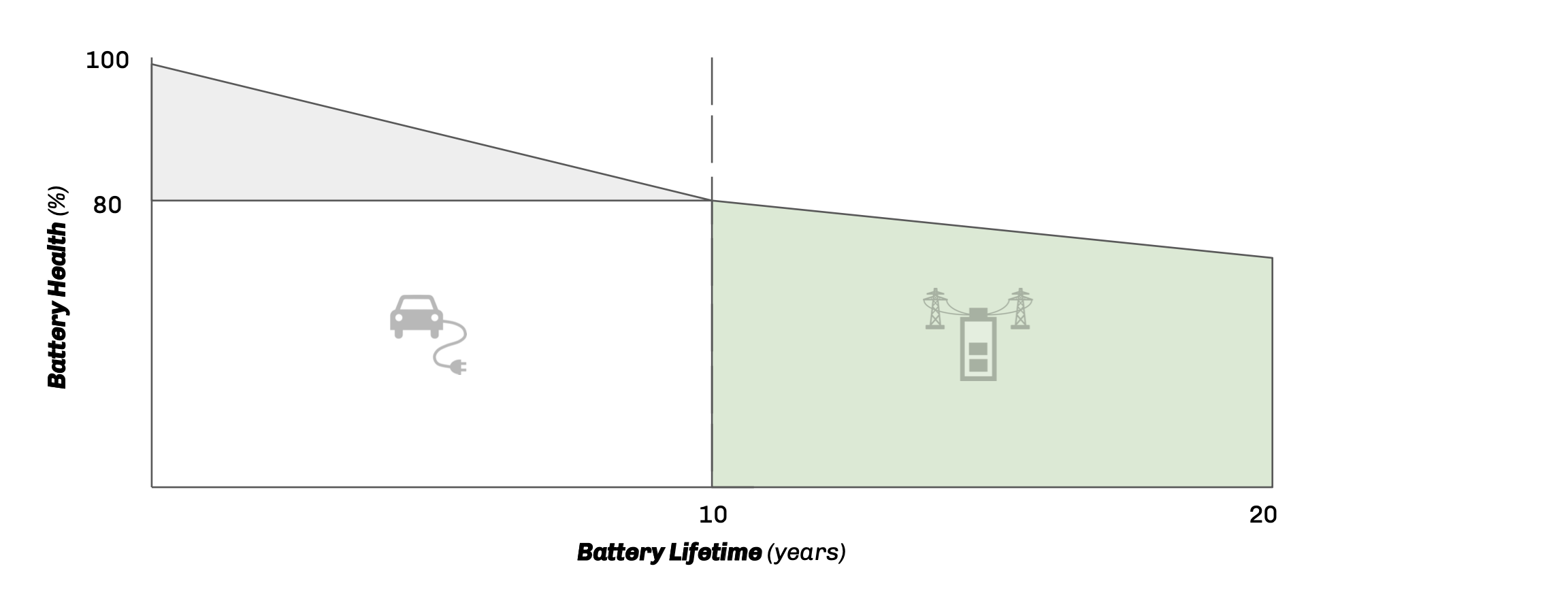

Global efforts to mitigate climate change through both e-mobility and energy storage face key barriers with Lithium-ion (Li-ion) batteries: uncertain performance, limited asset life, and end-of-life costs.

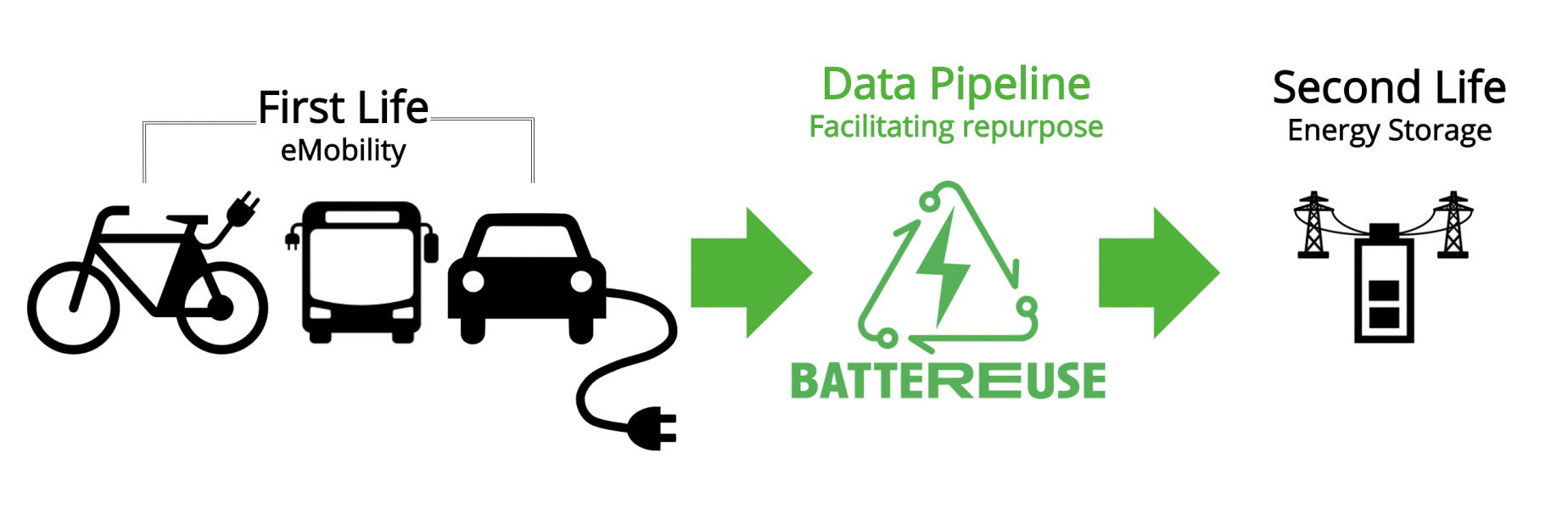

By collecting accurate data on historical usage & degradation using a novel physics-based battery management model, this project facilitates a circular economy for Li-ion batteries: repurposing retired Li-ion batteries into second-life energy storage systems can simultaneously save costs and reduce carbon emissions.

Did you know?

The difference between the carbon emissions savings of an electric vehicle vs a gas vehicle is only ~9-23%[1]. That assumes they are both driven to 100,000 kilometers. This is because there is an environmental impact to make the batteries in the EV. By getting a second life for those batteries in a less-intensive context, the carbon savings from the EVs are increased.

In order to move to the future we envision there is currently a lack of data that would show how this could be done.

Solution #

To address this problem, my team built a scalable framework to collect battery usage data & provide actionable repurposing insights. This involved the development of an ESS, data collection pipeline, configurable dashboard UI & battery management system (BMS).

The BMS incorporates BattGenie’s novel physics-based battery control algorithm, which provides accurate parameter estimation and lifespan extension compared to industry standards.

The GIX launch project is extensible to a second-life energy storage deployment, and may power the data collection for an Energy Storage System (ESS) to be used in a load-leveling & demand reduction for a local utility.

Extensive market & user research narrowed the focus to second-life applications: repurposing from e-transit into something that could plug into the grid. A wide variety of applications were evaluated, first focusing on e-bikes, but ultimately leveraging a partnership with a transit agency.

The team performed 20+ subject matter expert interviews with a wide variety of stakeholders across the battery lifecycle, including: cell manufacturers, system integrators, fleet owners, energy storage experts, second life battery repurposers, utilities, and recyclers. Based on these insights, the team refined business value proposition, and developed a prototype BMS with a customer-facing dashboard through two rounds of usability testing.

Hardware #

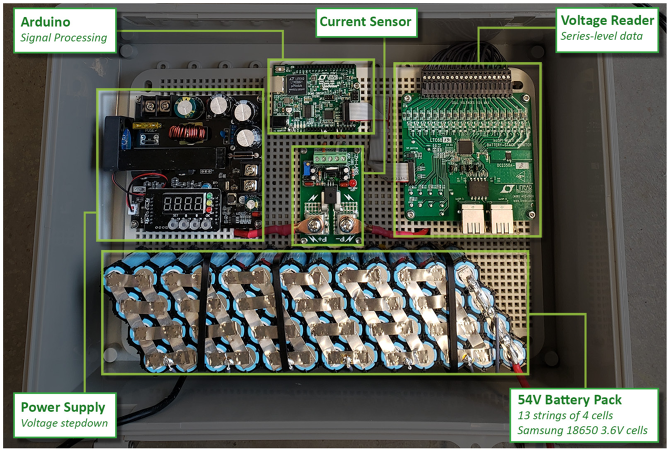

The hardware was chosed to showcase the proof-of-concept of BattGenie’s idea. To that end we needed a battery pack to use with BattGenie’s algorithm. We chose Samsung 18650 3.6V cells to mimic what’s going on inside King County Metro’s electric bus battery packs. We needed a way to measure the current and voltage, and a way to stepdown the battery back because strung together like that gives it 54V. The Arduino allowed send the data to the Raspberry Pi. It was all enclosed in an aftermarket pack and screwed into a breadboard for easy wiring.

Software #

Data Pipeline #

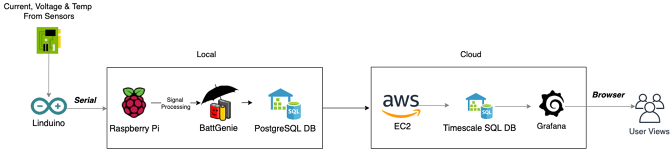

The data that would be useful to monitor originated from the batteries. There were 13 strings of batteries with 4 batteries in each string. The batteries were read by a voltage sensor and a current sensor. This was processed on the Arduino and then sent to the Raspberry Pi.

User Interface #

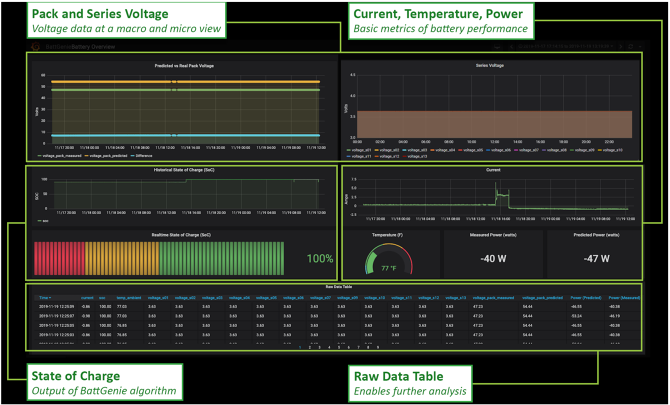

The user interface was a Grafana implementation that showed the current, voltage, and temperature of the batttery packs. It also showed the output from the BattGenie algorithm. The data was user tested with BattGenie to verify it was what they wanted.

Roadmap for BattGenie #

Our project was a prototype and an attempt at paving the way forward for Battgenie. They were able to secure some funding and you can find more about their future plans on their website.

My Specific Contributions #

Data pipeline #

I did the most work on the data pipline and getting the hardware to talk nicely with each other. This included everything from the current and voltage sensors interfacing with the Arduino, to sending that data to the Raspberry Pi and saving it in a local PostgreSQL DB. It also involved setting up the AWS EC2 instance and saving the data into a Timescale DB, which was necessary for the type of data we were working with and to display it properly in Grafana.

Stakeholder analysis / Market Fit #

As a group, we did a lot of stakeholder analysis for the different markets that we were considering as an entry point for this technology. We were thinking eBikes at first, but it turned out that the market forces weren’t right for our project. We all interviewed with SMEs in a variety of positions to get their idea of market viability.

What I didn’t do #

Once the data was in Grafana, I didn’t spend much time setting up the user views. That was the task for another teammate. Another thing I didn’t spend much time with was the battery pack. Including putting it together and setting up the voltage and current readers to the battery pack.

References #

More details are and references are included in our final presentation (2.8 MB).

The final poster is a succint visual to describe our project (9.2 MB).

[1] This paper compares the environmental impact of EVs to ICEs.